You are here

Belt Tensioners for Automotive Systems

Over 35 million NORGLIDE® Bearings supplied into belt tension systems every year!

Over 35 million NORGLIDE® Bearings supplied into belt tension systems every year!

Internal combustion engines need precision timing so the valves and piston heads work together fluidly. The timing mechanism is provided by mechanically linking the valves and piston heads together using the drive shaft and a timing chain or belt. Internal Combustion Engines (ICE) and mild-hybrid vehicles also have an accessory belt (commonly referred to as the Front End Accessory Drive or FEAD), which is used to power systems such as alternators, AC compressors, power steering, water pumps and starter generators.

For these systems to work efficiently, specific belt tension is needed. If the tension is too low, the belt can slip causing high noise and extra friction, which leads to elevated temperatures and high levels of wear. If the tension is too high, then there is a risk of causing high wear to the belt driven accessories as well as the belt tensioners and pulleys.

The belt tensioner device has an important role in maintaining the correct tension of the whole system, while at the same time maintaining belt alignment and providing the required damping effect. The device needs to be well aligned to function properly as a 1° increase in misalignment can result in an up to 30°C increase in belt temperature, which can often push the belt past its working temperature, causing excessive wear or even catastrophic failure.

Different engines require different damping and tensioning ratios, so belt tensioners tend to be designed for specific engines. The NORGLIDE® Bearing that is chosen has an important role to play in both the alignment and damping properties of the tensioning device, and Saint-Gobain engineers can work with you to ensure you specify the correct type for the required performance.

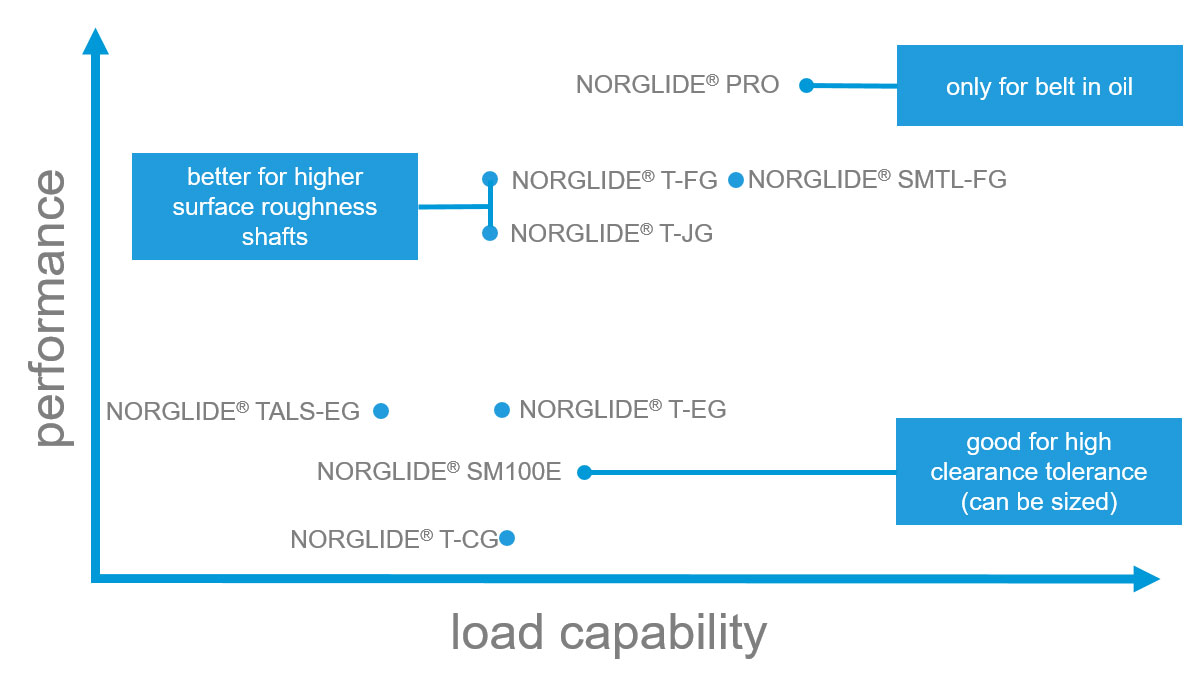

Material structures and performance

Due to the complexities in design, the choice of material for the bearing is very important and depends on many factors. Surface roughness of shafts, loading conditions, belt tensioner axis offset and corrosion protection are just some of the factors that will affect the material selection and our engineers can guide you through this process.

Tensioner

|

NORGLIDE®

|

Typical

|

Criteria for

|

|---|---|---|---|

|

Accessory: |

T |

CG / E / EG |

|

|

Accessory: |

T / TAL / SM |

E / EG / JG |

As above, plus:

|

| Timing belt |

H / PRO |

E / FG |

Higher temperature |

To run smoothly and efficiently, some bearings will require expensive surface finishing of the shaft, which comes at an increased cost. The unique sliding layer in NORGLIDE® Bearings comprise PTFE compounds that are designed to perform well with a selection of different surface finishing treatments. This enables our customers to reduce the costs of manufacturing the mating components.

To run smoothly and efficiently, some bearings will require expensive surface finishing of the shaft, which comes at an increased cost. The unique sliding layer in NORGLIDE® Bearings comprise PTFE compounds that are designed to perform well with a selection of different surface finishing treatments. This enables our customers to reduce the costs of manufacturing the mating components.

ICEs can produce unwanted torsional vibrations in the drive shaft, which can be transmitted to the accessory and timing belts. It is important to damp or isolate torsional vibrations to ensure smooth and efficient power transfer, with low noise.

ICEs can produce unwanted torsional vibrations in the drive shaft, which can be transmitted to the accessory and timing belts. It is important to damp or isolate torsional vibrations to ensure smooth and efficient power transfer, with low noise. The thick PTFE layer in NORGLIDE® Bearings has damping properties that can absorb the torsional vibrations, improving the whole system.

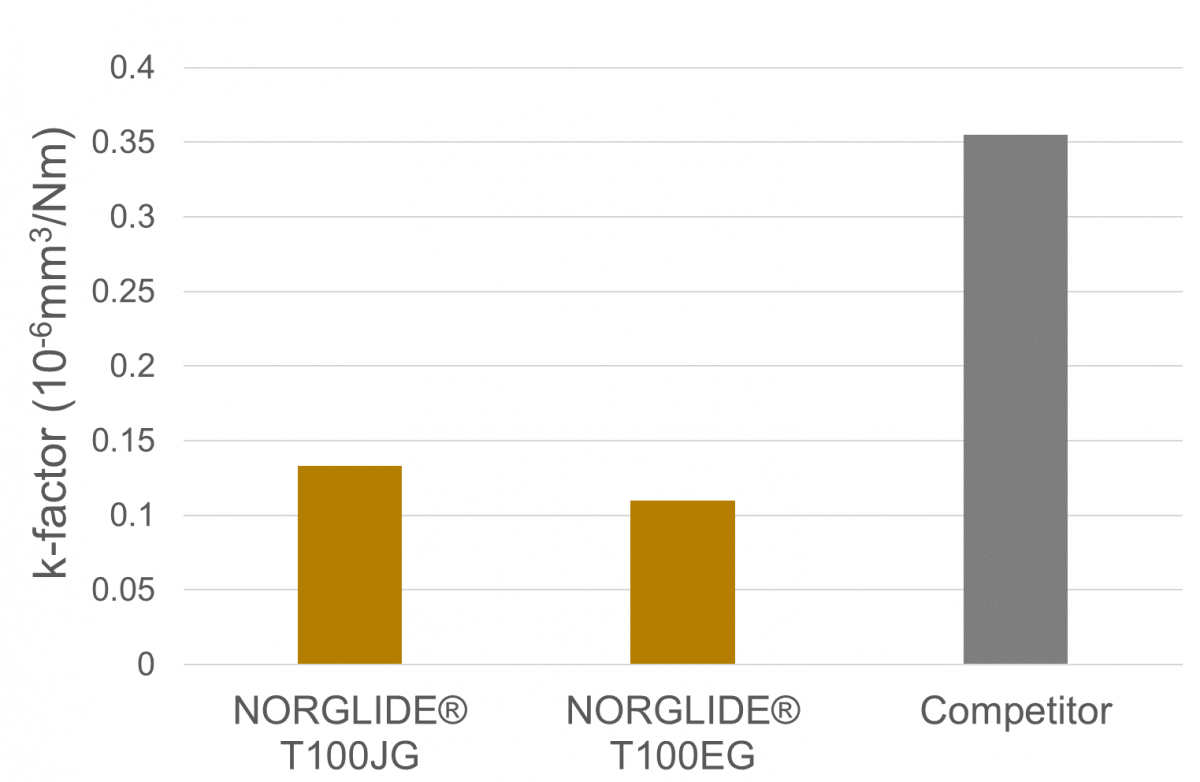

Improving wear properties and maintaining better clearances over life.

Improving wear properties and maintaining better clearances over life.

For the same level of friction as alternative bearing choices, NORGLIDE® Bearings have a much reduced wear rate meaning NORGLIDE® Bearings maintain better clearances over the lifetime of the belt tensioner.

Improving corrosion properties in accessory tensioners with NORGLIDE® material selection.

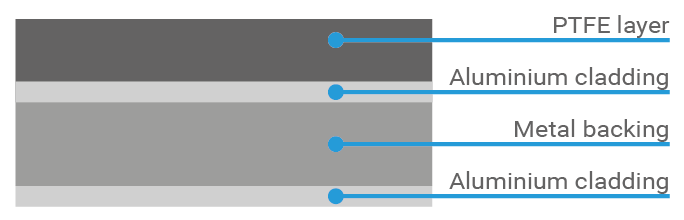

Bearings that are made from steel are at risk of corrosion in exposed environments such as the engine bay. In these applications, corrosion protection is required and NORGLIDE® Bearings have several options that can be used depending on the demands of the application.

For medium levels of corrosion protection, zinc plating can be used. If the bearing is a small one, then mechanical zinc plating can be performed in-house by Saint-Gobain. For larger bearings such as those in dual arm tensioners, then zinc electro-plating is used.

NORGLIDE® Bearings that are exposed to more extreme environments or for applications where the housings are zinc plated, the metal backing layer can be aluminium or in applications that require a higher load capacity, aluminium clad steel.